The following key factors should be considered when selecting crane wire ropes:

parallel laid steel wire ropes are more preferred, as they have a long service life. cross laid steel wire ropes are more flexible but have poor wear-resistance performance.

Depending on the scenario, fiber cores are suitable for general lifting and are self-lubricated, while steel cores are used in high-temperature or heavy-load environments.

Safety factor: Generally, it is 4-6 times to ensure that the breaking force is greater than the calculated load value (e.g., at least 980 kN for a 20-ton load).

Lifting method: The lifting angle affects the load-bearing capacity (the load drops by approximately 30% at a 45-degree angle). When multiple wire ropes are working together, the diameter must be adjusted and the angle factor must be considered.

Working environment: Metal core ropes are selected for high-temperature environments, and hot-dip galvanized steel wire ropes are used for corrosive environments.

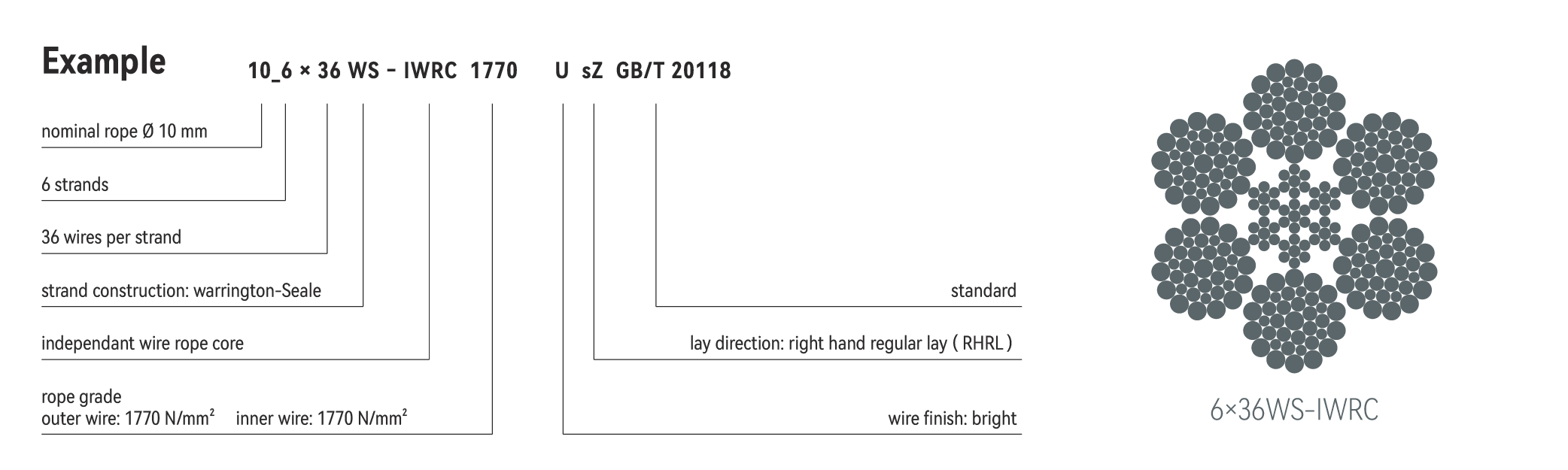

For small-tonnage cranes, the main hoist rope is typically a 6×36 series wire rope, with either IWRC or SFC cores.

For medium- to large-tonnage cranes, the main hoist rope is typically a rotation-resistant wire rope, such as the 18×7 series, 24(W)×7 series, and 35(W)×7 series. Some equipment also uses the 4×V39 series. These wire ropes offer excellent rotation resistance, significantly reducing the risk of self-rotation when suspended loads. They prevent accidents caused by entanglement, kinking, and whipping, significantly improving operator controllability, especially in high-lift tower cranes and port cranes. Their special structural design increases the contact area with the pulleys, resulting in over 30% greater wear resistance than standard 6-strand ropes. If the equipment requires higher minimum breaking strength and wear resistance, anti-rotation compaction strand wire ropes, such as the 18×K7 series, 24(W)×K7 series, and 35(W)×K7 series, can be used.

Luffing wire ropes are typically 8×K19 and 8×K36 series, with an IWRC core. Their wear resistance is over 30% higher than that of ordinary round strand wire ropes, making them suitable for pulley systems with frequent bending.

Auxiliary wire ropes for other non-critical areas are generally 6×19 series.

Note: The above comments are for reference only. Please consult a professional engineer for advice on crane rope selection.