Proper maintenance of wire rope-related equipment components is crucial to the life of the rope.

Excessively worn pulley grooves and other severely worn parts can cause excessive vibration, which in turn exacerbates metal fatigue.

Poor pulley alignment can lead to rope wear and wear on the pulley flange.

When the wire rope passes over the pulley or is wound onto the drum, the sharp angles can cause significant wear, especially on drums with multiple layers of winding.

Groove radius should be measured regularly.

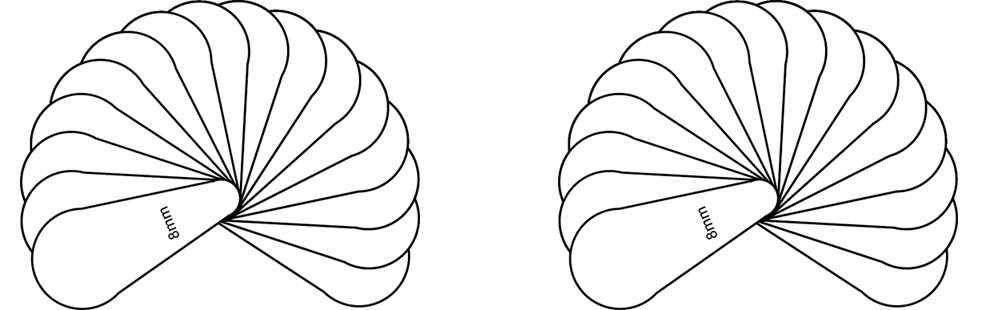

When inspecting pulleys and drums, the most important item to check is groove wear. A groove gauge is recommended.

For new or reworked grooves, and to verify the suitability of new wire ropes, the groove gauge should be 1% larger than the maximum allowable positive tolerance of the new rope. Alternatively, the pulley groove size must be 1% larger than the actual diameter of the wire rope to be installed.